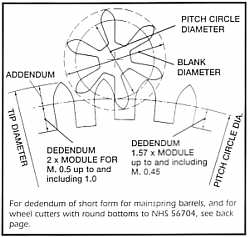

Module M = Diameter in mm D divided by Number of teeth N + addendum.

Also Module = Twice the center distance in mm divided by Sum of teeth in wheel + pinion

Center Distance = M divided by 2 multiplied by sum of teeth in wheel and pinion

Module = 25.4 divided by the D P

Diametral Pitch = 25.4 divided by Module

Blank Diameter = Module multiplied by N + Addendum allowance from the table below.

Example: For a pinion of 6 leaves and a Module of 0.7 the Blank Diameter = 0.7 X (6 +1.71) = 5.397mm

To calculate the module of a wheel or pinion when the center distance is not known.Module = Diameter divided by N + addendum allowance

For pinions of odd numbered leaves use a hole gauge to measure the diameter.

| Number of leaves | Ogive | Ratio tooth/space | Add to number of teeth or leaves |

| 6 | Full | 1/2 | 1.71 |

| 7 | Full | 1/2 | 1.71 |

| 8 | Full | 1/2 | 1.71 |

| 10 | 1/3 | 2/3 | 1.61 |

| 12 | 1/3 | 2/3 | 1.61 |

| 16 | 1/3 | 2/3 | 1.61 |

| Wheel | . | 1/1 | 2.76 |

For cutting pinions on old clocks with thicker leaves use cutter 0,05 module smaller than the

calculated one.

The addendum allowance is unchanged.

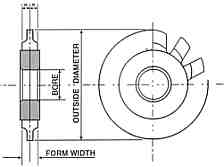

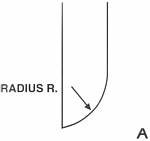

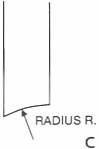

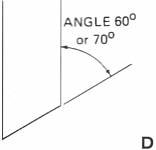

The profiles are made in accordance with BS978 Part 2 NHS56702/3 and have square bottoms,

also NHS 56704 with round bottoms. These cutters can be re sharpened without loss of form.

We can supply suitable grinding wheels.

The cutters are relieved using profile ground solid carbide tools, the finish on the cutter teeth is therefore of a high quality.

All cutters are made from 8% Cobalt M42 (HSS-E) high speed steel hardened and treble tempered under vacuum, therefore no change in the surface chemistry of the tool. This steel is of first quality, and is known for its ability to keep a good cutting edge and to give long duration between sharpening. Hardness is circa 68 ROCKWELL C.

For cutting carbon steel pinions with high speed steel cutters

Cutter diameter 14mm 430-500 rpm. Cutter diameter 20mm 300-350 rpm.

Cutter diameter 24mm 250-290 rpm. Cutter diameter 26mm 230-270 rpm.

A copious stream of cutting oil should be used to keep the cutter cool and remove the chips. Mobilmet 745 or similar. Pinions should never be cut dry.

For cutting brass a speed of up to 3-4000 can be used, but a much lower speed will preserve the tooth cutting edges.

Brass for wheels should be hard or half-hard leaded engraving brass such as CZ120 or CZ118, CZ119, with a hardness of 120-130 VNP. Do not use soft brass which will clog the cutter and spoil the work.

Steel clock pinions may be cut from silver steel which has been fully annealed (it is supplied in normalized condition) but steels with a lower carbon content such as EN8 or EN9 are to be preferred.

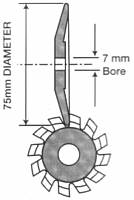

For sharpening High Speed and carbon Steel wheel and pinion cutters, we recommend Green Silicon Carbide grinding wheels with a vitrified bond and cool cutting. Grit: GC 220. Hardness: HS. Bond: VG. Dished Form. Diameter 75mm. Bore: 7mm. High grade CBN (Borazon)wheels are also available, mounted on resinal or aluminium, dimensions are normally the same.

These are fine tooth cutters not form relieved and cannot be sharpened,the diameter is 26mm.

Bore 7.0mm. Number of teeth on cutter 60. In table below the pith is the pitch of the escape wheel

less Tooth Tip thickness in mm.

| Cutter N0. | Radius in mm. | Pitch in mm. | Cutter thickness in mm. |

| 1E | 3.28 | 1.31 | 1.64 |

| 2E | 4.10 | 1.64 | 2.05 |

| 3E | 5.12 | 2.05 | 2.56 |

| 4E | 6.40 | 2.50 | 3.20 |

| 5E | 8.00 | 3.20 | 4.00 |

| 6E | 10.00 | 4.00 | 4.50 |

| 7E | 12.25 | 5.00 | 5.80 |

These are fine tooth cutters not form relieved and cannot be sharpened,the diameter is 30mm. Bore 7.0mm.

Number of teeth in cutter is 60. these cutters are designed for a 30 tooth escape wheel, but pitch

and number of teeth may be varied up to about 9 percent.

These are fine tooth cutters not form relieved and cannot be sharpened,the diameter is 30mm. Bore 7.0mm.

Number of teeth in cutter is 60. these cutters are designed for a 30 tooth escape wheel, but pitch

and number of teeth may be varied up to about 9 percent.

Example of calculating escape wheel tooth

pitch.

Tip diameter=1.375". Number of teeth = 29 Pitch = pie x diam divided by number of teeth this

is 3.142 x 1.375 divided by 29 = 0.148 inches, so use cutter size B dead beat.

| Size | Diam of scape wheel in inches | Pitch less tip thickness in inches |

| A | 1.75 | 0.183 |

| B | 1.42 | 0.148 |

| C | 1.08 | 0.113 |

| D | 0.75 | 0.078 |

These are fine tooth cutters not form relieved and cannot be sharpened,the diameter is 30mm. Bore 7.0mm.

Number of teeth in cutter is 60.

| Radius in mm. | Diameter of ratchet in mm | Thickness / Pitch in mm. |

| 4 | 8 | 3 |

| 6 | 12 | 4 |

| 9 | 18 | 6 |

| 13.5 | 27 | 9 |

These are form relieved cutters with a diameter of 28mm and a 7.0mm bore.Number of teeth on

cutter is 12, cutter thickness 7mm.

These are form relieved cutters with a diameter of 25mm and a 7.0mm bore.Number of teeth on

cutter is 12.

| Size | Pitch in mm | Depth in mm | Tip width of cutter in mm. | Cutter thickness |

| 00 | 0.63 | 0.52 | 0.20 | 2.00 |

| 0 | 0.82 | 0.67 | 0.26 | 3.00 |

| 1 | 1.10 | 0.90 | 0.35 | 3.00 |

| 2 | 1.40 | 1.15 | 0.45 | 3.00 |

| 3 | 1.80 | 1.47 | 0.57 | 3.00 |

| 4 | 2.30 | 1.88 | 0.73 | 3.25 |